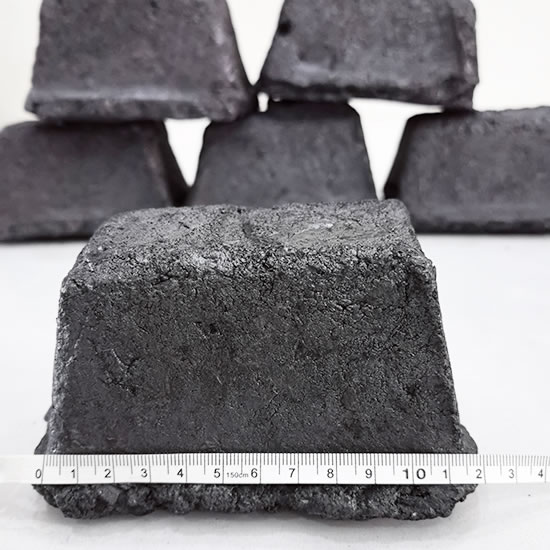

Block Electrode Paste

Block Electrode Paste is a composite material composed of several key components. The primary constituent is the active material, which varies depending on the intended application. Common active materials used in Block Electrode Paste include graphite, carbon black, metal oxides, and conductive polymers. These materials possess excellent electrical conductivity and provide a high surface area for electrochemical reactions.

In addition to the active material, the paste also contains a binder, which is typically a polymer resin. The binder serves as a matrix that holds the active material particles together and provides mechanical strength to the electrode. Various types of binders can be employed, such as polyvinylidene fluoride (PVDF), carboxymethyl cellulose (CMC), and styrene-butadiene rubber (SBR).

Furthermore, Block Electrode Paste incorporates conductive additives, such as carbon nanotubes or metallic powders, to enhance the overall conductivity of the electrode. These additives create a conductive network within the paste, facilitating efficient electron transport during electrochemical reactions.

Block Electrode Paste finds extensive use in a wide range of electrochemical applications. Some notable applications include:

Battery manufacturing: Block Electrode Paste is a critical component in the fabrication of rechargeable batteries, such as lithium-ion batteries, lead-acid batteries, and nickel-metal hydride batteries. It serves as the active material in the positive and negative electrodes, enabling the storage and release of electrical energy during charging and discharging cycles.

Fuel cells: Electrode paste is also utilized in the production of fuel cells, which convert chemical energy into electrical energy. It acts as the catalyst support material in the electrodes, facilitating the electrochemical reactions involved in the generation of electricity.

Supercapacitors: Block Electrode Paste is used in the construction of supercapacitors, which store electrical energy via electrostatic double-layer capacitance or pseudocapacitance. The high electrical conductivity and large surface area of the paste contribute to the enhanced energy storage capabilities of supercapacitors.

Electrowinning and electrorefining: In the metallurgical industry, electrode paste is employed in processes like electrowinning and electrorefining of metals. These processes involve the deposition or extraction of metals from electrolytes, and the electrode paste serves as the active material for these electrochemical reactions.

| project | unit | Sealed paste | Standard electrode paste | Chemical electrode paste | |||

|---|---|---|---|---|---|---|---|

| No. 1 | No.2 | No.2 | No.2 | No.3 | |||

| Ash or less | % | 4.0 | 6.0 | 7.0 | 9.0 | 11.0 | 11.0 |

| Volatile flux or less | % | 12.0~15.5 | 12.0~15.5 | 9.5~13.5 | 11.5~15.5 | 11.5~15.5 | 11.0~15.5 |

| The compressive strength or greater | MPa | 18.0 | 17.0 | 22.0 | 21.0 | 20.0 | 18.0 |

| The resistivity or less | μΩm | 65 | 75 | 80 | 85 | 90 | 90 |

| Volume density p G/cm after |

g/cm³ | 1.38 | 1.38 | 1.38 | 1.38 | 1.38 | 1.38 |

| elongation | % | 5~20 | 5~20 | 5~30 | 15~40 | 15~40 | 5~25 |

| brand project |

Ash or less | Volatile flux or less | The compressive strength or greater | The resistivity or less | Volume density p G/cm after |

elongation |

|---|---|---|---|---|---|---|

| No.1 | 3.0 | 12-15.5 | 23 | 65 | 1.46 | 6-20 |

| No.2 | 3.0 | 12-15.5 | 23 | 75 | 1.43 | 5-20 |

Zhengshan Technology is the reason for becoming a Block Electrode Paste long-term partner. The key word "integrity and win-win" Zhengshan Technology's business philosophy can be summed up in eight words: "honesty based, win-win development". Zhengshan Technology has always implemented this concept well for both its internal employees and external Block Electrode Paste partners, thus gaining long-term good business reputation and cooperative relations in the Battery manufacturing field, and promoting the stable development of Zhengshan Technology.