Egg Shaped Electrodes Paste

Goose Egg Electrode Paste

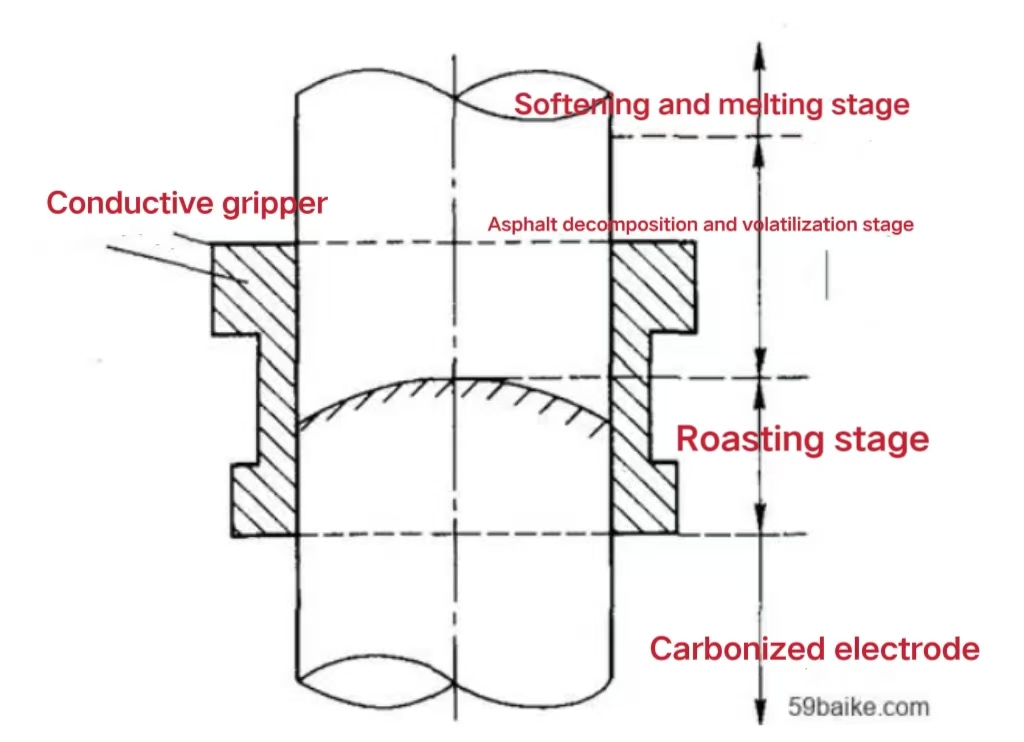

Electrode paste is a conductive material used for electric furnace equipment such as ferroalloy furnaces and calcium carbide furnaces. Electrode paste, also known as self baking electrode, relies on the heat inside the ore furnace to complete the baking process. Therefore, matching the consumption rate of the electrode with the baking rate is the key to the use of electrode paste. Due to the development of ore furnace technology, it is gradually moving towards larger and more enclosed directions. During the baking process, the electrode can only reduce the amount of conductive and radiative heat obtained from the open furnace type in the past, which is only conductive heat. Therefore, the heat obtained by the electrode from the furnace is greatly reduced. This requires improving the sintering performance of the electrode paste to make up for this deficiency.

Technical Parameter

Low Ash Content: Goose Egg Electrode Paste typically has a low ash content, minimizing unwanted impurities in the furnace and reducing the risk of slag formation.

| project | unit | Sealed paste | Standard electrode paste | Chemical electrode paste | |||

|---|---|---|---|---|---|---|---|

| No. 1 | No.2 | No.2 | No.2 | No.3 | |||

| Ash or less | % | 4.0 | 6.0 | 7.0 | 9.0 | 11.0 | 11.0 |

| Volatile flux or less | % | 12.0~15.5 | 12.0~15.5 | 9.5~13.5 | 11.5~15.5 | 11.5~15.5 | 11.0~15.5 |

| The compressive strength or greater | MPa | 18.0 | 17.0 | 22.0 | 21.0 | 20.0 | 18.0 |

| The resistivity or less | μΩm | 65 | 75 | 80 | 85 | 90 | 90 |

| Volume density p G/cm after |

g/cm³ | 1.38 | 1.38 | 1.38 | 1.38 | 1.38 | 1.38 |

| elongation | % | 5~20 | 5~20 | 5~30 | 15~40 | 15~40 | 5~25 |

| brand project |

Ash or less | Volatile flux or less | The compressive strength or greater | The resistivity or less | Volume density p G/cm after |

elongation |

|---|---|---|---|---|---|---|

| No.1 | 3.0 | 12-15.5 | 23 | 65 | 1.46 | 6-20 |

| No.2 | 3.0 | 12-15.5 | 23 | 75 | 1.43 | 5-20 |

Working principle of electrode paste

The working principle of electrode paste mainly relies on the heat inside the mineral thermal furnace to complete the roasting, and achieves conductivity through the self roasting process. The key to use is to match the consumption rate of electrode paste with the firing rate. With the development of submerged arc furnace technology, the usage conditions of electrode paste are constantly changing to adapt to the trend of large-scale and enclosed development.

Production site

Application of electrode paste

Electrode paste is mainly used in the fields of ferroalloys, calcium carbide, grinding tools, electronic appliances, environmental protection, and medical care.

User visits

Mode of transport

FAQ

1:Your specifications are not very suitable for us. Please provide us with specific indicators through TM or email. We will give you feedback as soon as possible.

2: When can I get the price? We usually provide a quotation within 24 hours after receiving your detailed requirements, such as size, quantity, etc. If it's an urgent order, you can call us directly.

- Do you provide samples? Yes, the samples are available for you to check our quality. The sample delivery time is about 3-10 days.

- What is the delivery time for bulk products? The delivery time is based on quantity, approximately 7-15 days. For graphite products, applying for a dual-use item license takes approximately 15-20 working days.

- What are your delivery terms? We accept FOB, CFR, CIF, EXW, etc. You can choose the most convenient way. besides, We can also air freight and express delivery.

6. Product packaging? We use bulk carriers or ton bags for packaging, or place them in containers according to your requirements.

Zhengshan Technology is based on the advantages of Calcium carbide furnace industry, and its core point is "pay attention to talents" Calcium carbide furnace Egg Shaped Electrodes Paste service providers -- Zhengshan Technology believes that a good Zhengshan Technology enterprise will pay attention to talent cultivation. Then, the development of Egg Shaped Electrodes Paste enterprise training is particularly important. First of all, training is the need of Calcium carbide furnace service enterprises to participate in market competition. Under the current situation, the competition of Calcium carbide furnace enterprises is ultimately the competition of Egg Shaped Electrodes Paste technical talents. In addition to cooperating with Calcium carbide furnace professional and technical colleges to recruit suitable talents, the more effective way is to improve the Egg Shaped Electrodes Paste professional and technical quality of existing employees through Calcium carbide furnace industry training, so that they can become Egg Shaped Electrodes Paste technical talents to meet the needs of Calcium carbide furnace enterprises.